📌 Introduction: Plastics in Our Daily Life

It is very difficult to imagine our lives today without plastics. They are everywhere around us: in bottles, shopping bags, electrical devices, and even cars.

In Egypt, the plastics industry is one of the most important and fastest-growing industries. It provides job opportunities, utilizes locally available raw materials,

and meets the high demand of the local market.

But how do these raw materials – plastic pellets – turn into the final products we use every day? The answer lies in plastic forming machines, which are considered

the heart and brain of any modern plastics factory.

⚙️ How is Plastic Formed?

Plastic forming machines take plastic pellets, heat them until they become liquid and flexible, then press them into molds designed according to the required final product.

After cooling, the product is fully formed and ready for use.

🔹 Main Plastic Forming Methods

- Injection Molding: High precision method for solid products. Examples: storage boxes, chairs, appliance parts, packaging molds.

- Blow Molding: Perfect for hollow products. Examples: water bottles, juice containers, detergent bottles, toy packaging.

- Extrusion (Continuous Forming): For long, fixed-shape products. Examples: pipes, irrigation hoses, plastic sheets.

- Thermoforming: Heating plastic rolls and shaping them with molds. Examples: food trays, packaging covers, toy packaging.

🏭 Key Industries Using Plastic Forming Machines

- Packaging & Food Industry: cups, trays, wrapping, and food covers.

- Home Appliances: refrigerator, washing machine, and fan parts.

- Automotive: dashboards, door handles, interior decoration parts.

- Agriculture: irrigation systems, hoses, pots, planting containers.

- Medical Sector: syringes, medical tubes, disposable instruments.

- Toys & Education: dolls, toy cars, Lego blocks, puzzles, school supplies.

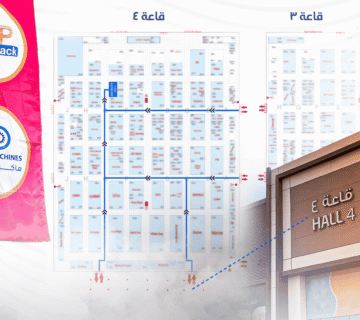

🤝 Infinity Machines: Your Local Industrial Partner

Infinity Machines is not just a supplier of plastic forming machines, but a trusted local partner that cares about the success of its clients.

Being a local manufacturer allows the company to provide quick technical support, machine upgrades, and professional training.

✨ Why Choose Infinity Machines?

- 🔧 Fast Support: Quick access to maintenance and updates.

- 🎓 Professional Training: Easy and practical training for operating teams.

- 🏅 High Quality: Machines built with top materials for long life.

- ⚡ Energy Saving: Designed to reduce power consumption and costs.

- 💰 Competitive Prices: Global quality with local pricing.

🛠️ Main Plastic Forming Machines by Infinity

- Thermoforming Machine: For product covers, food trays, toy and candy packaging molds.

- Roller Press (Cutting Machine): Cuts thermoformed plastic into separate pieces. Easy to use with high productivity.

- Side Folding Blister: For folding card edges using heating and quick cooling.

- Heat Sealing Press: Seals paper card with plastic using heat and pressure.

📍 Conclusion

If you are thinking about starting a plastics factory or upgrading your current one, choosing the right machine is the most important step.

With Infinity Machines, you don’t just buy a machine—you gain a local partner who provides training, support, and expertise to ensure your production success.