Introduction

The silk screen printing machine is one of the most essential tools in industrial and artistic printing. It’s used to print designs on a wide range of surfaces such as fabric, plastic, glass, metal, paper, and wood. Although this technique has existed for decades, it continues to evolve to meet the needs of modern production. In this article, we cover everything from the history to the latest innovations in silk screen printing machines.

The History of Silk Screen Printing

Silk screen printing originated in ancient China and gradually developed into an industrial method by the early 20th century. It was widely adopted in Europe and the U.S. during World War II for printing military uniforms, posters, and logos. Over time, semi-automatic and fully automatic machines emerged, offering efficient printing solutions across various industries.

How Does a Silk Screen Printing Machine Work?

The machine pushes ink through a mesh screen (typically made of synthetic silk or nylon) stretched over a metal frame. The design is prepared using photosensitive materials and exposed to light to create a stencil.

Steps:

Prepare the screen with the design template.

Place the product (e.g., T-shirt or plastic container) on the printing table.

Use a squeegee to push ink through the open areas of the stencil.

Dry the ink using heat or UV light, depending on the type of ink used.

Types of Inks Used

Different inks are chosen depending on the material:

Plastisol Ink: Common in textile printing; cures with heat.

Water-based Ink: Eco-friendly, suitable for cotton fabrics.

UV Ink: Cures instantly under UV light; used for glass, plastics.

Solvent Ink: For hard surfaces like metal and glass.

Types of Silk Screen Printing Machines

Manual Machines: Ideal for small workshops; requires full human handling.

Semi-Automatic Machines: Combines manual and automated controls for medium-sized production.

Fully Automatic Machines: High-speed, precise machines for industrial-scale production.

Recent Technological Advancements

Modern machines come with advanced features such as:

Digital control systems (PLC).

Automatic drying using IR or UV systems.

Servo motors for speed and precision.

High alignment accuracy for multi-color prints.

Applications of Silk Screen Printing

This versatile machine is used for:

T-shirt and sportswear printing.

Printing on plastic bottles and packaging.

Cardboard and industrial packaging.

Printing on metal and electronic components.

Wood and decorative printing.

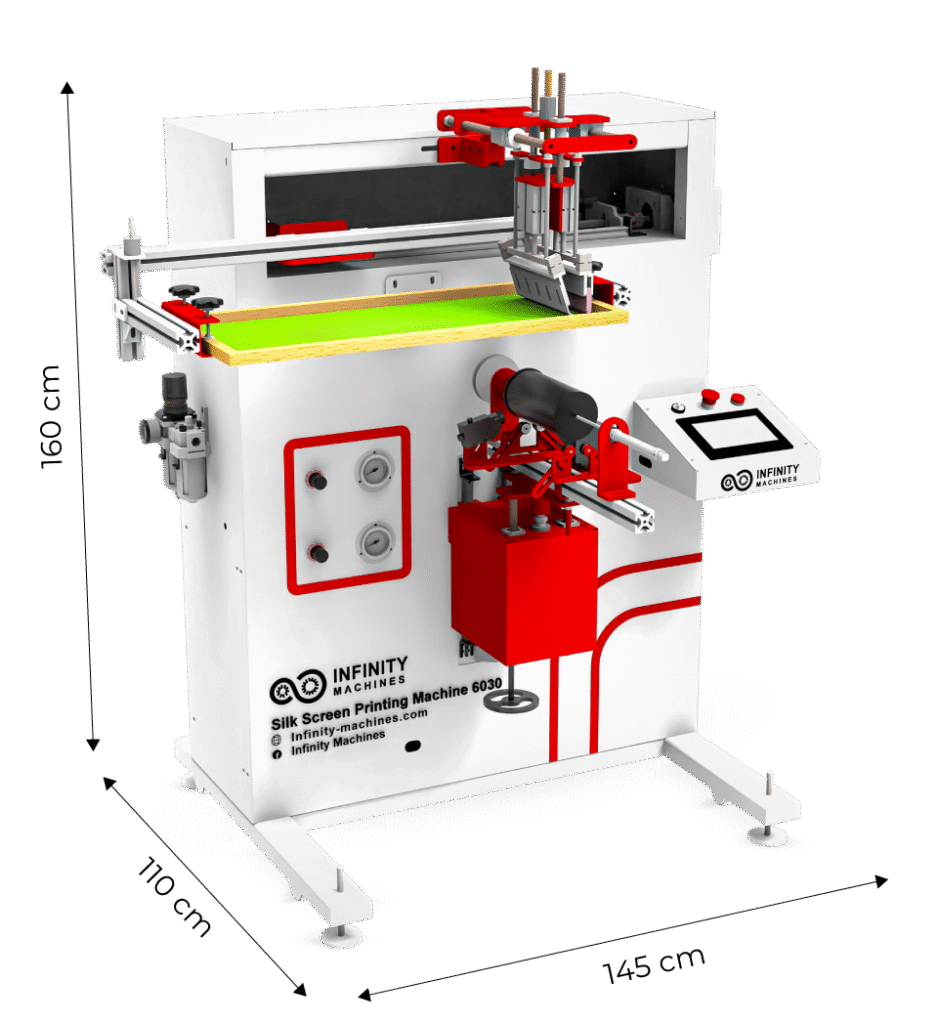

Why Choose Infinity Machines EG?

At Infinity Machines EG, we offer:

High-quality screen printing machines at competitive prices.

Customizable machines based on your production needs.

Free training and after-sales service.

Genuine spare parts with fast delivery.

Contact Us

Looking for a screen printing machine for your factory or startup?

Contact our expert team at Infinity Machines EG for a customized quote or message us on WhatsApp to schedule a free consultation.