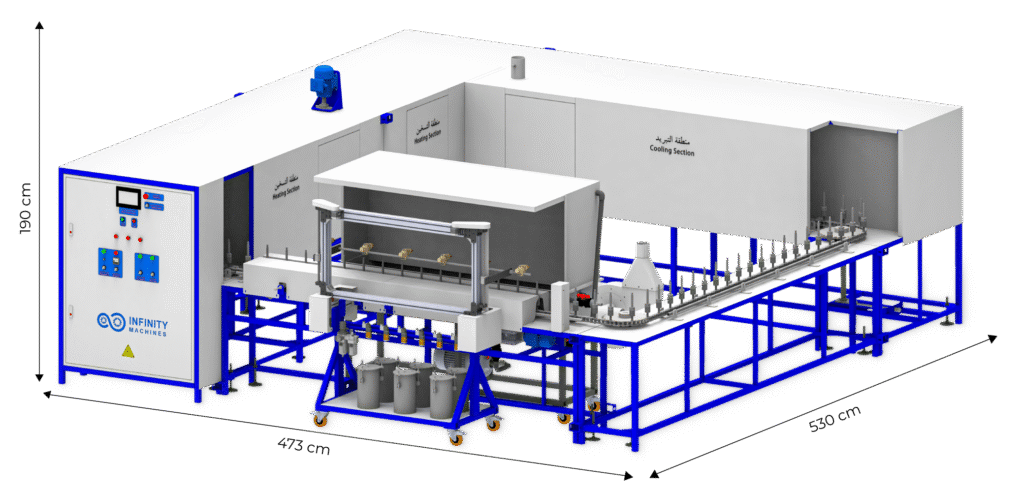

Color Spray Line

The spraying line consists of more than one stage to ensure the highest productivity and best efficiency :

1. Spraying stage with 6 spray guns equipped with color tanks and mixer to ensure color homogeneity .

2. Spraying stage equipped with horizontal movement and vertical movement for easy spraying of all pieces .

3. The oven contains a set of heaters to ensure achieving the required temperature for the colors as well as an air blower to ensure temperature homogeneity through which a temperature of 200 ℃ can be achieved .

4. Cooling stage through which the pieces can be cooled slowly so that they do not shock them with the natural external temperature .

5. Unloading and loading stage through which the final pieces can be unloaded and the new pieces required for spraying can be placed .

6. This line can be implemented according to customer request .

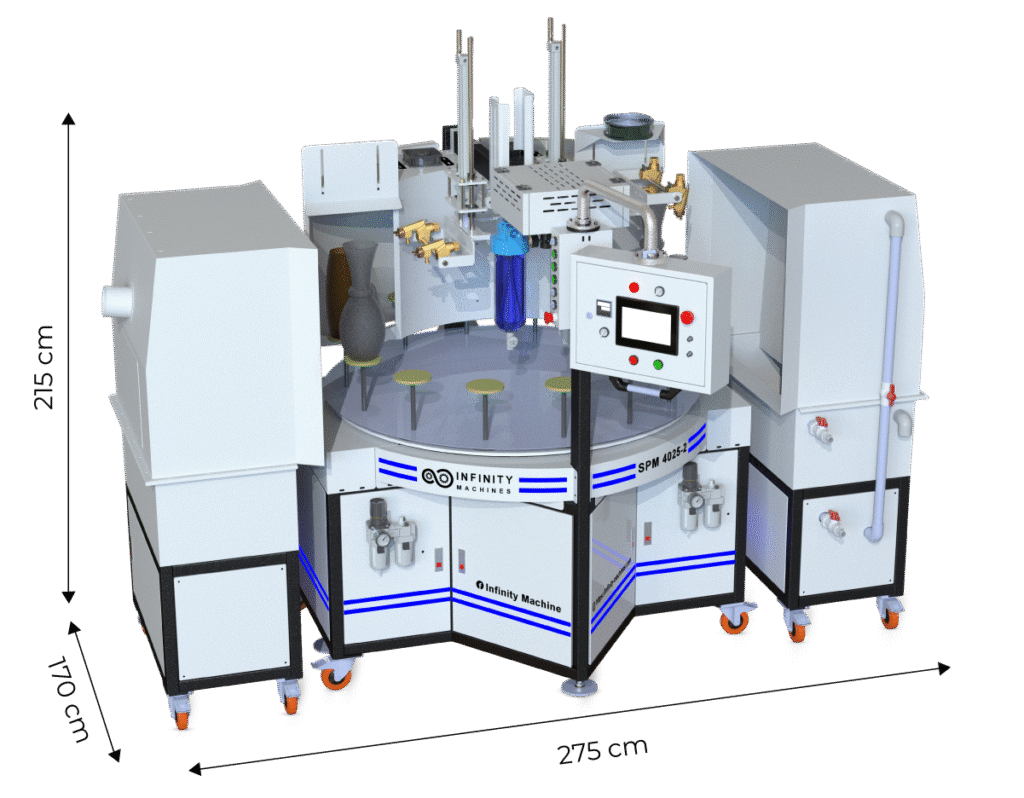

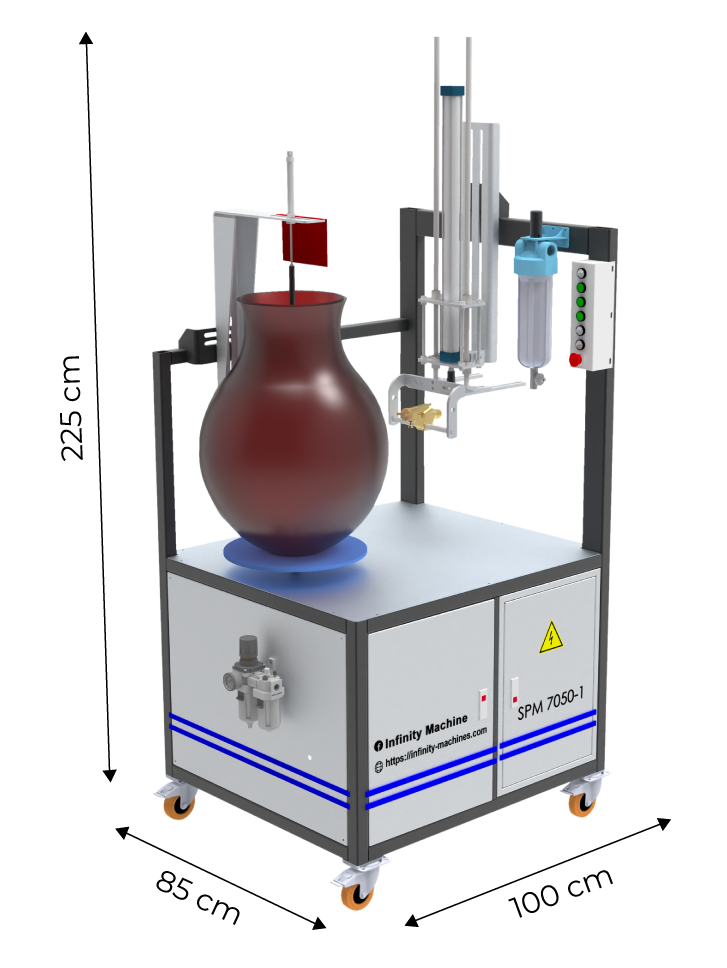

Color Spray Machine

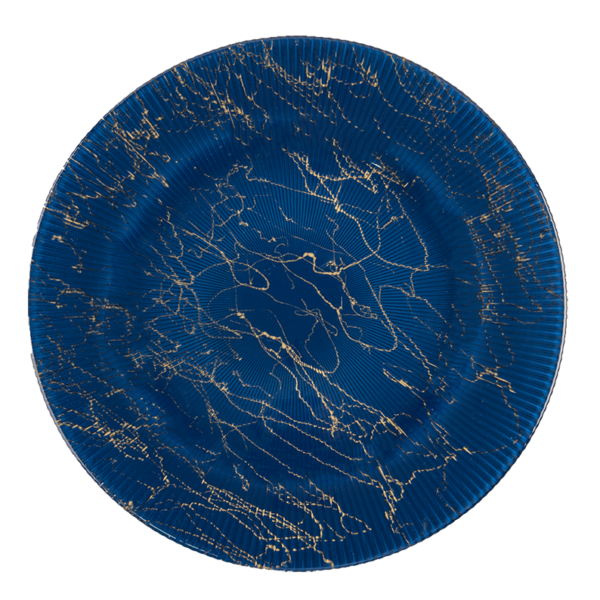

- The color spray machine creates a thin layer of the desired color and gradation in color for all types of glass and non-glass pieces .

- It contains 12 heads to install the pieces which two pieces are sprayed at the same time.

- The machine is characterized by productivity and ease of handling for spraying any desired shape .

1- Rotary Tray

2- Single Head

Machine specifications

- We can add spraying water curtain unit which reduces the dust from spraying process With power of 1 KW

- Heating unit can be added before or after spraying stage or both With power of 2 KW To hold the piece after spraying easily .