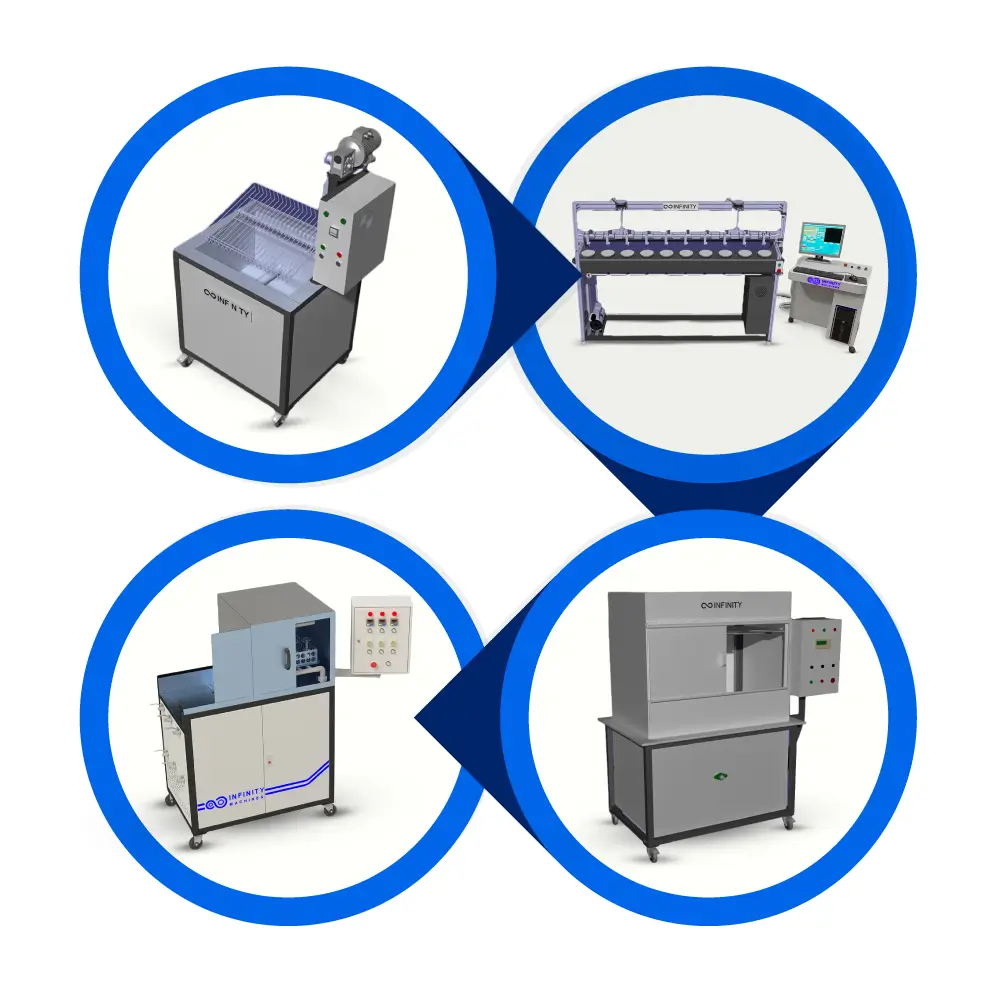

The pantograph line is used to engrave glass and crystal using the wax and acid method to produce shiny engraving. It consists of four machines: a wax, engraving, acid and washing machine .

It is used in manufacturing the line , Raw materials do not react with the acids used , Each machine contains its own safety Procedures for the safety of the worker and the factory , Using The

latest software for design and implementation .

1- Wax Machine:

This machine melts the wax used in the basin (made of stainless steel) up to a temperature of 90 degrees in order to allow the user to download the required glass for the required period and then leave it outside the machine so that it solidifies forming a thin layer of wax on the required glass)

- – The number of pieces = 15-20 pieces/cycle

- – Maximum height = 40 cm

- – Cycle time = 20 seconds to 5 minutes

- – Electricity = 220/380 volts

- – Power = 6.5 kW

- – Safety systems = electricity

- – Operating system = automatic

- Machine size: Length: 105 cm – Width: 73 cm – Height: 173 cm.

- Machine weight: 120 kg

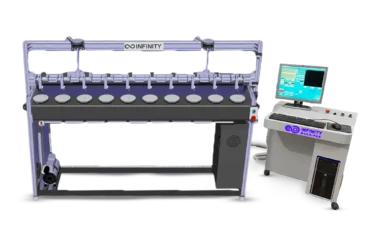

2- Engraving Needle Machine:

This machine disperses the wax layer according to the required design on pieces of glass and crystal of various circular, square and irregular shapes by means of the latest programs for design and implementation through this machine with three axes to ensure an excellent level of emptying without cutting.

- – Number of Heads= 10 / 8 / 6 Heads

- – Productivity = 1 piece / minute (average)

- – The largest diameter = 14 / 23 / 28 cm

- – Maximum height = 37 cm

- – Electricity = 220 volts

- – Power = 600 watts

- – Safety systems = electricity

- – Operating system = computer

- Machine size: Length: 300 cm – Width: 70 cm – Height: 160 cm.

- Machine weight: 160 kg

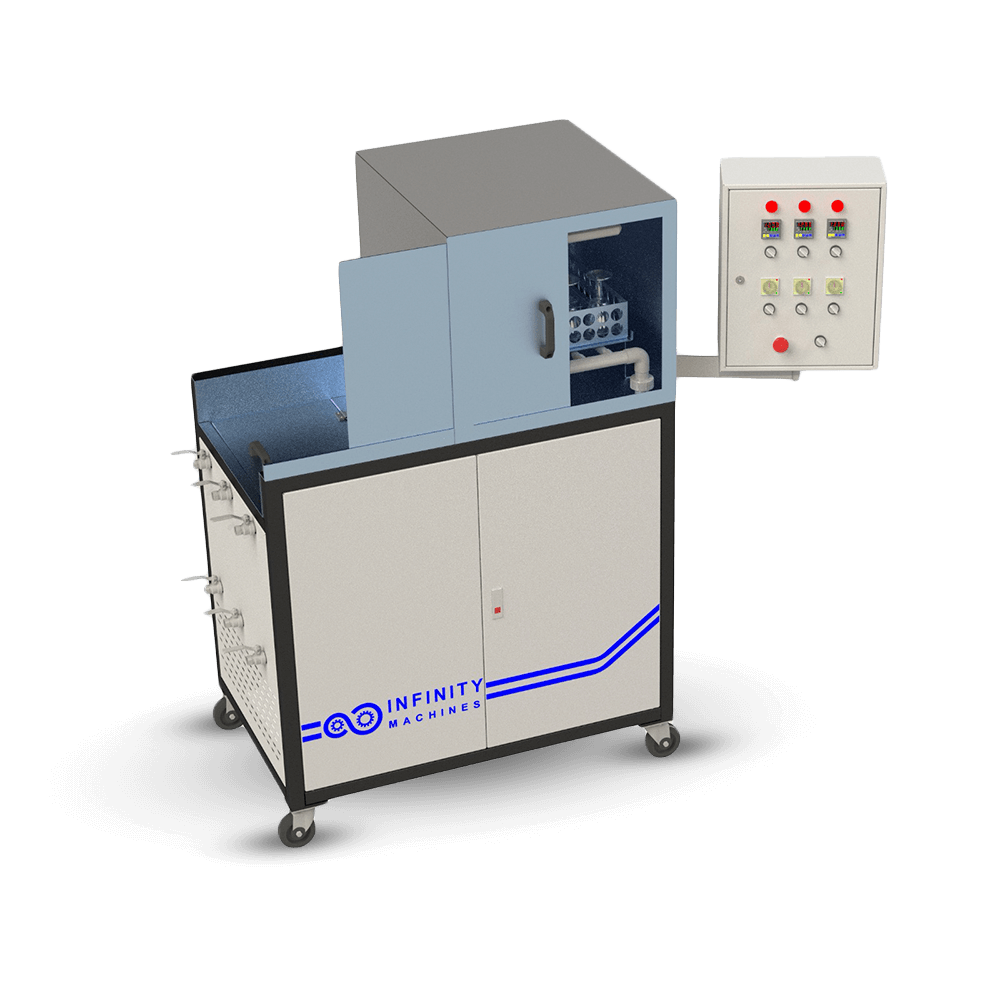

3- Acid Machine:

This machine lowers the different pieces of glass into the acid basin in order to etch the glass through the chemical reaction between the glass and the acid in order to give a bright etch with high accuracy, then it washes the pieces with water to allow the worker to deal directly without any danger.

This machine is made of raw materials that resist acids, water and salts.

- – The number of pieces = 15-20 pieces/cycle

- – Maximum height = 45 cm

- – Cycle time = up to 10 minutes with repetition allowed

- – Electricity = 220/380 volts

- – Power = 750 watts

- – Safety systems = electricity / mechanics

- – Operating system = automatic

- Machine size: Length: 180 cm – Width: 96 cm – Height: 192 cm.

- Machine weight: 120 kg

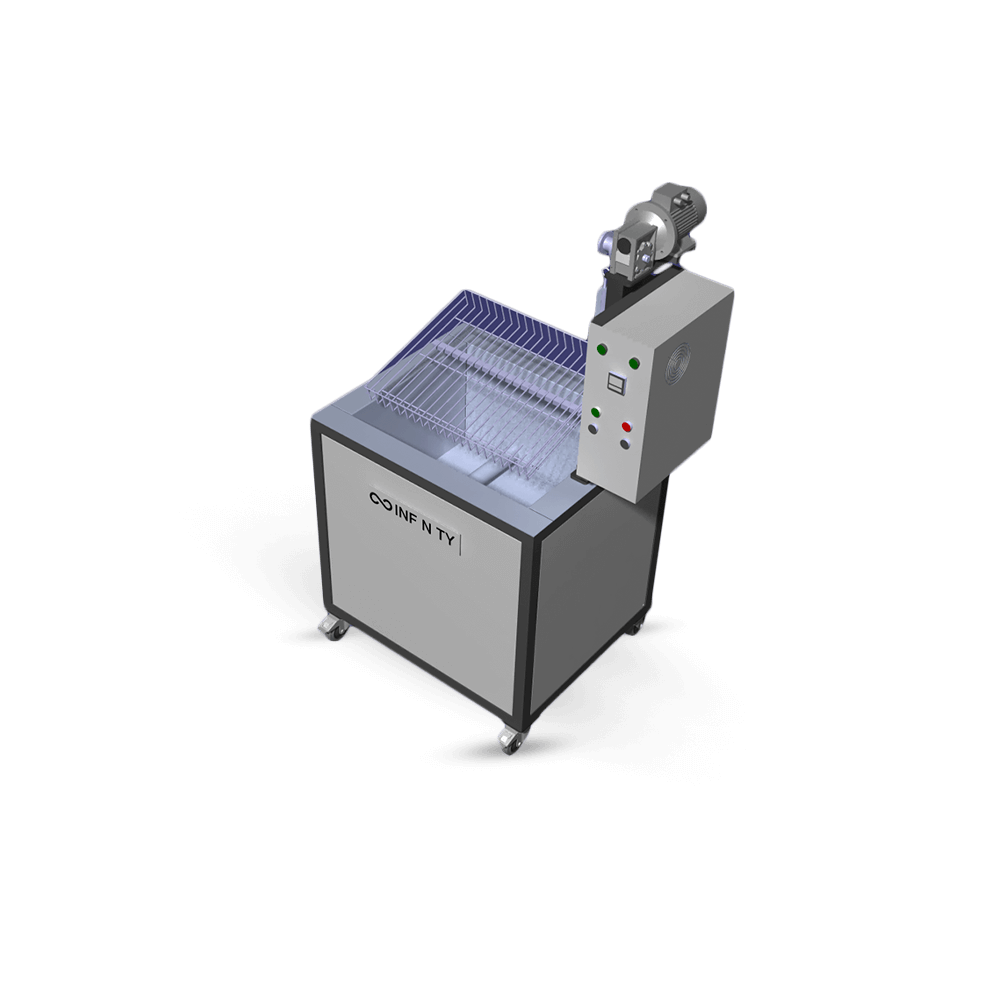

4- Washing Machine:

This machine washes the glass pieces with hot water up to 95 degrees until the entire wax layer is removed from the required pieces through two stages of washing (the washing cycle is a closed cycle to save water use).

- – The number of pieces = 15-20 pieces/cycle

- – The number of stages = 2/3 stages

- – Maximum height = 45 cm

- – Cycle time = 10 seconds with repetition allowed

- – Electricity = 220/380 volts

- – Power = 7.5 kW

- – Safety systems = electricity

- – Operating system = automatic

- Machine size: Length: 162 cm – Width: 75 cm – Height: 183 cm.

- Machine weight: 160 kg